Wafer Tape Out

Content of tape out

Relying on the long-term relationship with the main-stream foundries local and oversea, we provide customers with turnkey service. With efficient operation and bargaining power, reduced customer costs and shorten research and development (R&D) cycle, We can provide related data and service of Si process (0.35um~6nm) and SiC process, including MPW&Full mask tape out, Mass-production management.

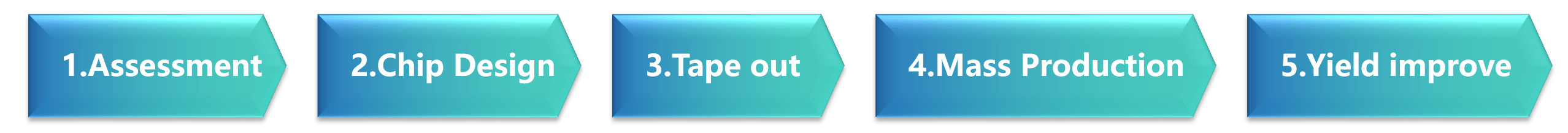

Procedure of tape out

The procedure, from the assessment of requirement feasibility to final mass production, follows the five-step procedure to ensure the development and the delivery of stable and reliable products:

NPI control of tape out

1. Multi-solutions to prevent data breach and ensure customer design data security.

2. Full NPI procedure, follow specific SOP to ensure tape out smoothly, according to the following four stages:

Tape-out project

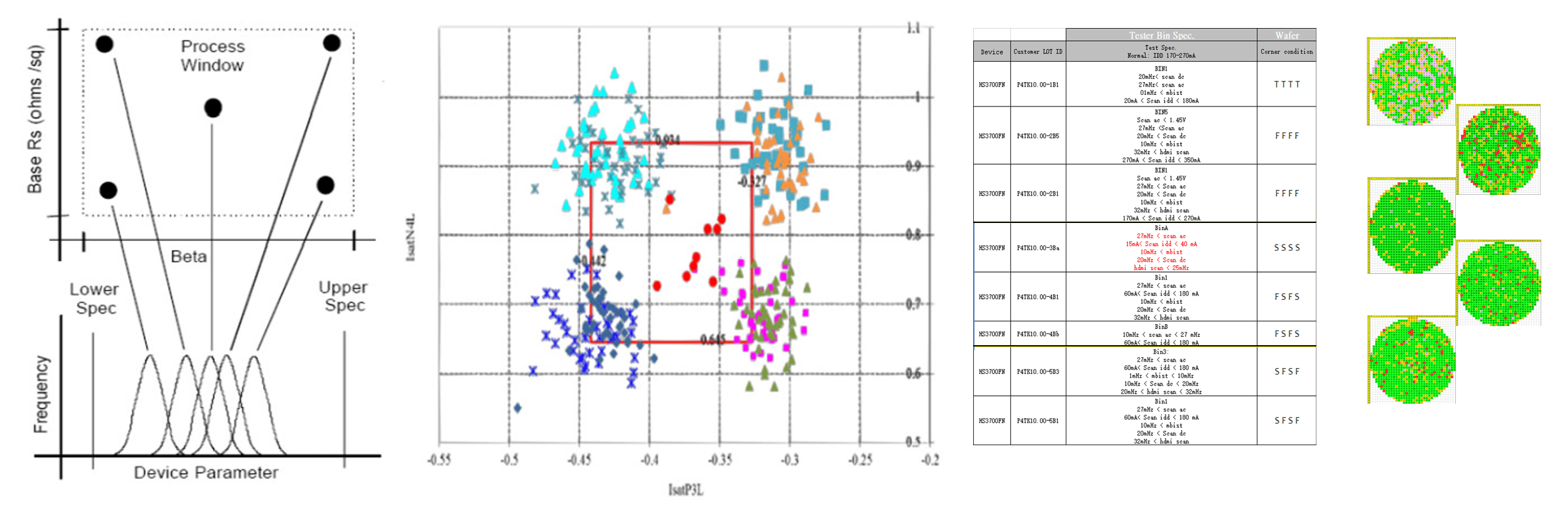

1. LYG assists customers with complete analysis and monitoring from product design, tape-out, verification, until the introduction of mass production to reduce the risk of abnormal product failure:

- Assist customers with Tape Out import operations

- Collect and analyze production measurement data, make yield improvement plan, and feed back to the fab and sealed test plant for yield improvement

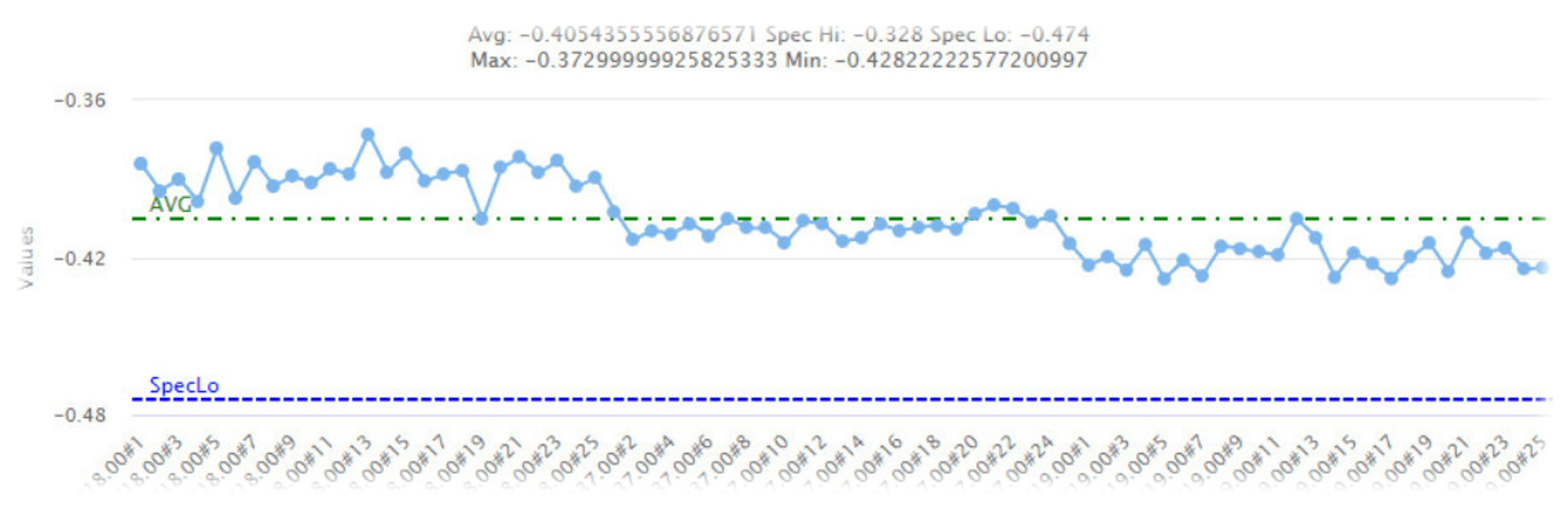

- Establish a baseline of product characteristics to monitor production conditions and reduce the risk of product anomalies

- Develop a Corner split lot plan to verify product characteristics under extreme process conditions

- Assist customers in product failure analysis, identify product weaknesses, and develop reinforcement plans

Corner Split Lot Verification

Monitor Process with Period Trend Chart

2. The WAT/CP/Assy/FT data of B2B upload from Foundry/OSAT, and identify production abnomalies through real-time analysis tools to solve low-yield problems efficiently:

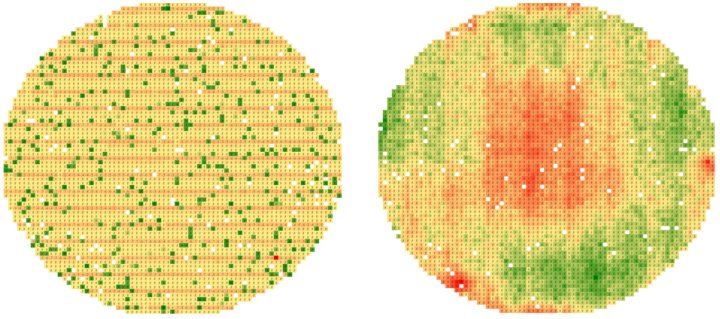

Inspect CP value distribution and detect site issues

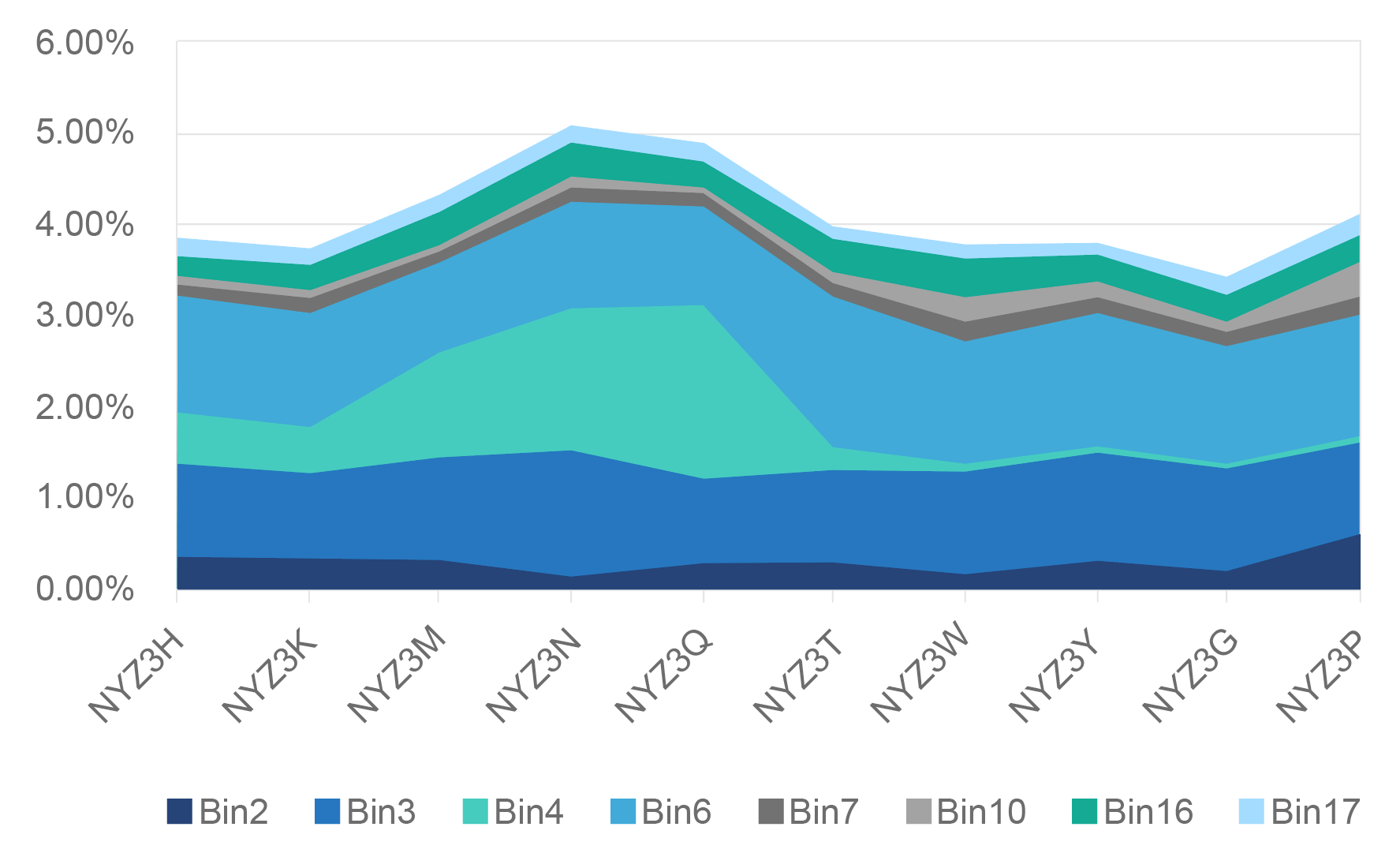

Inspect major fail bins to find out the production abnormalities

Key suppliers

Key suppliers include the foundry of local and oversea: