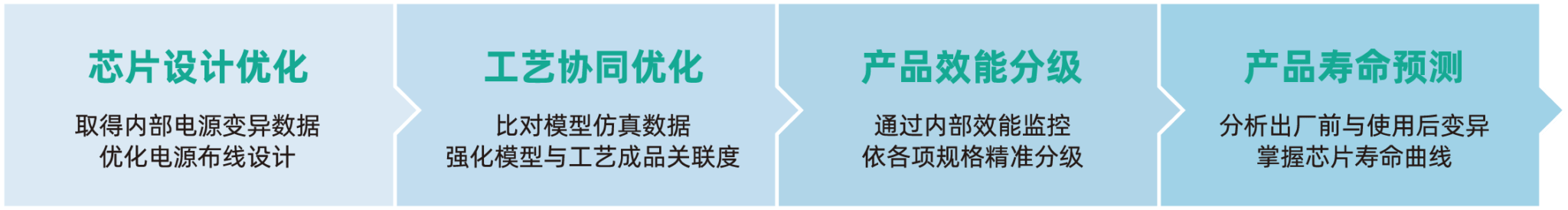

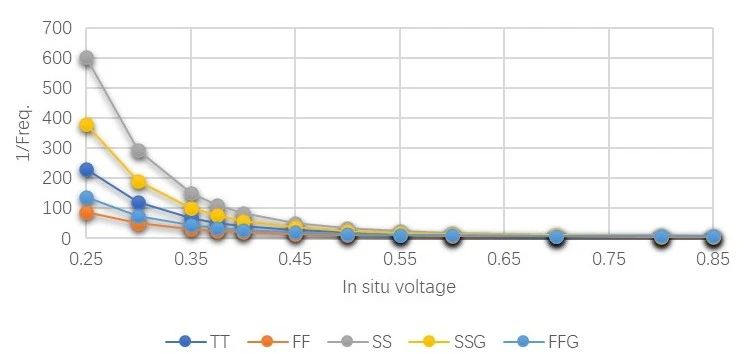

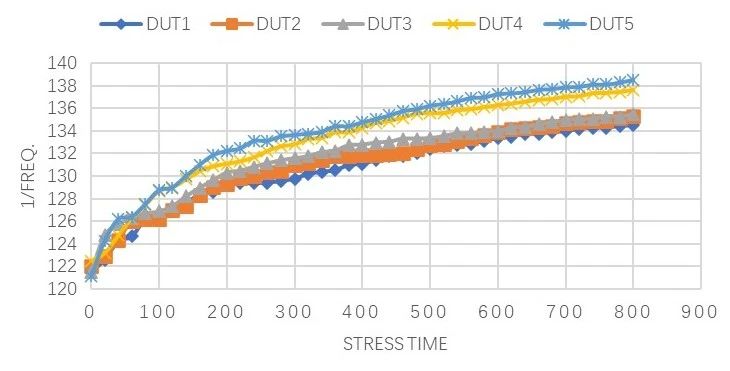

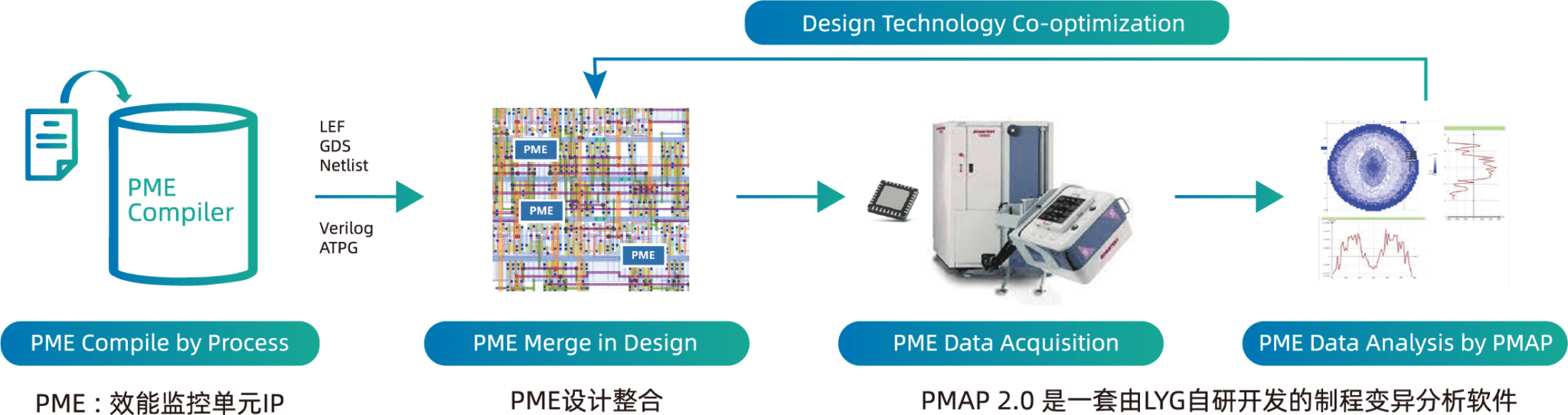

In the integrated chip performance and yield improvement services, we provide complete hardware and software solutions, from the IP of the wafer manufacturing variation detection system to the corresponding analysis software, to solve the design and manufacturing problems of chip design companies. Different from the traditional Wafer Acceptance Test (WAT), which mainly measures the relationship between the current and voltage of components, only the static characteristics of components can be monitored. We combine the Performance Monitoring Element with the Performance Monitoring Analysis Platform, and through the serial output port of the chip, Extract real-time performance data from each chip before, after, and even during system operation to achieve chip design optimization, process improvement, product classification, and performance and lifetime analysis.

Variable parameters that affect chip performance

1

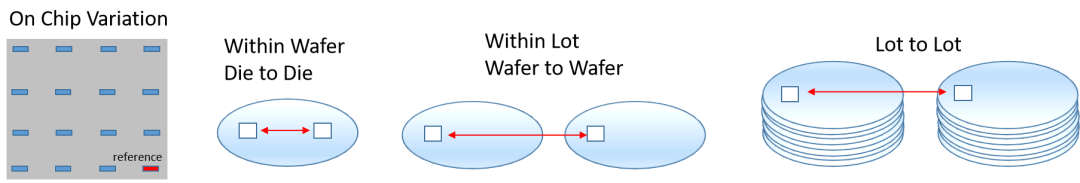

Process Variation (制程差异)

– On Chip Variation (within-die OCV)

– Global Variation (Die-to-Die, Wafer-to-Wafer, Lot-to-Lot)

2

Process Variation (制程差异)

– Static & Dynamic IR drop

– Within Chip, Off-Chip

3

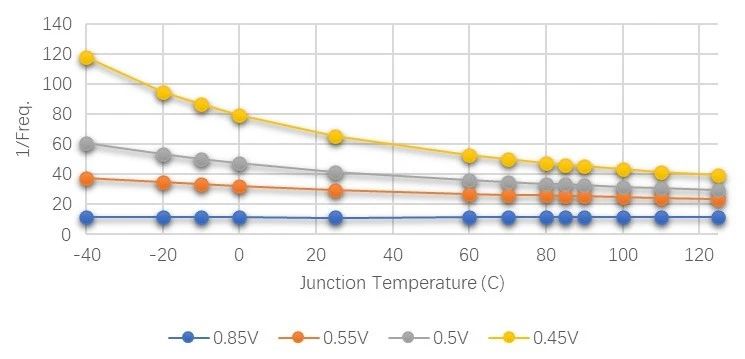

Operating Temperature Variation

(温度差异)

4

Aging Effect (芯片老化)

DTCO方法

The new generation of semiconductor processes is becoming more and more complex, and more and more process parameters need to be adjusted. Because semiconductor processes are provided to different customers, DTCO uses customers' specific designs to examine the variation of PVT on chips, and provides the direction for wafer fab to evaluate and adjust process parameters. Therefore, DTCO enables the corresponding circuit design and process optimization to maximize the process advantages brought by advanced semiconductor nodes to the chip.

With experts from TSMC and Intel in DTCO, Lingyange is one of the few companies capable of providing DTCO chip design services in China, and is a leader in the industry.